DIY Headers

+14

TommyK

bbf-falcon

bowsher21

richter69

whatbumper

bonfire

res0rli9

1982GT

Race Ready Fabrications

69F100

Mustang-junky

jbozzelle

bruno

MustangBBF

18 posters

Page 1 of 2

Page 1 of 2 • 1, 2

Re: DIY Headers

Re: DIY Headers

Setting the expectation now: I am a shade tree mechanic. Stuff gets done but don't expect show quality. lol.

MustangBBF- Posts : 36

Join date : 2015-06-10

Re: DIY Headers

Re: DIY Headers

All of that is why we get $2000 for our mild steel headers with mufflers. And they are perfect in the end. We have a lot of experience that can not be shared not because we don't want to but because it just takes time to learn it.

we dont use any kind of mock up kits. we place the collector where we want it bolt the flanges on the heads and put a 6" or so piece of hose on the plugs to take up space so you don't make it hard to change plugs. then get after it.

we dont use any kind of mock up kits. we place the collector where we want it bolt the flanges on the heads and put a 6" or so piece of hose on the plugs to take up space so you don't make it hard to change plugs. then get after it.

whatbumper- Posts : 3024

Join date : 2009-11-11

Age : 43

Re: DIY Headers

Re: DIY Headers

^ agree..... Ive always put the flanges on and stuck the collector where it needed to be andgot after it.

richter69- Posts : 13649

Join date : 2008-12-02

Age : 53

Location : In the winners circle

Re: DIY Headers

Re: DIY Headers

I like to use a standup band saw to cut the tube and you should get a nice 10" or 12" disc sander to face off your tubes after cutting. That will square the faces up for an excellent fit. The better the fit, the better the weld and the better the finished product.

bowsher21- Posts : 100

Join date : 2010-05-10

Location : Northern IL.

Re: DIY Headers

Re: DIY Headers

How would a piece of Flex tubing work to mock up a tube? would this work or no?

bbf-falcon- Posts : 8995

Join date : 2008-12-03

Location : Jackson, Ohio

Re: DIY Headers

Re: DIY Headers

bbf-falcon wrote:How would a piece of Flex tubing work to mock up a tube? would this work or no?

There are any number of ways to setup a visual models such as using flex tube. The hard part is transferring it to tube length and angle of cut. I use short sections of 1/8 tig weld wire for distance and angle.

Check this out, If I did more sets of headers I might think about getting this setup.

http://www.jefflilly.com/fabrication/header-fabrication/

bowsher21- Posts : 100

Join date : 2010-05-10

Location : Northern IL.

Re: DIY Headers

Re: DIY Headers

http://www.stainlessheaders.com/headerfabrication

TommyK- Posts : 74

Join date : 2009-08-09

Location : CT

Re: DIY Headers

Re: DIY Headers

bowsher21 wrote:bbf-falcon wrote:How would a piece of Flex tubing work to mock up a tube? would this work or no?

There are any number of ways to setup a visual models such as using flex tube. The hard part is transferring it to tube length and angle of cut. I use short sections of 1/8 tig weld wire for distance and angle.

Check this out, If I did more sets of headers I might think about getting this setup.

http://www.jefflilly.com/fabrication/header-fabrication/

That is some pretty bad ass info right there.

jasonf- BBF CONTRIBUTOR

- Posts : 2992

Join date : 2009-07-14

Age : 54

Location : Lafayette, LA

Re: DIY Headers

Re: DIY Headers

i seen somewhere looked like they were using those foam noodles that kids use to float in the pool they had them stuck in the flanges and then bent where they needed them to go and I guess copy that with header tube maybe stick a tig wire in the middle to keep it how you want

Super Snake Steve- Posts : 141

Join date : 2012-07-18

Re: DIY Headers

Re: DIY Headers

All great ideas. Like to idea of the 6" pieces of hose to account for plug accessibility. Neat trick. Jeff. Lolly link is awesome and the stainless headers link too. MystangBbf. I still look forward to your effort. Will be nice to see something that isn't professional just so I know I'm not alone in this hobby. In the days of Internet some days I feel like I'm the dopiest untalented auto enthusiast in the nation. Seems like everyone can weld 20 gauge aluminum and make it look like a piece of art. Maybe it's just that those who can't do that don't post pics of their work

bonfire- Posts : 28

Join date : 2009-09-05

Re: DIY Headers

Re: DIY Headers

Have to agree with the K.I.S.S. header building approach. Bolt on the flange, put the collector where you want it, & start stacking tubing to fill in the rest.

Some of the "tricks" for mocking up the header tube shape before actually cutting the first actual J-bend (like flexible tubing, welding rod, pvc tubing, etc) are pretty much a waste of time/money IMO. The flex tubing never really accurately represents a tight radius J-bend, & pvc straight's & elbows are even worse. And the welding rod trick might give you a basic idea of the bend, but not how the actual bent tubing will stack against it's neighbor. So in the end you are still making an educated guess when using the mock-up stuff.....just like you would if you just started with the actual J-bend instead.

If you absolutely can't get the header job done without using some form of tube mock-up tool, a better idea IMO is to just buy an extra J-bend & sacrifice it (by chopping it up giving you various lengths of straights & bend angles) to use as mock-up tools.

About the only "header making tool" I have ever found that really does help is using a simple hose clamp to align the weld joint between two pieces of header tubing before you tack them. Just take a regular SS hose clamp & drill 3 or 4 holes around the band. The 3-4 holes don't need to be real big, just big enough to have enough room to get a the tiny tack welds in there.

Some of the "tricks" for mocking up the header tube shape before actually cutting the first actual J-bend (like flexible tubing, welding rod, pvc tubing, etc) are pretty much a waste of time/money IMO. The flex tubing never really accurately represents a tight radius J-bend, & pvc straight's & elbows are even worse. And the welding rod trick might give you a basic idea of the bend, but not how the actual bent tubing will stack against it's neighbor. So in the end you are still making an educated guess when using the mock-up stuff.....just like you would if you just started with the actual J-bend instead.

If you absolutely can't get the header job done without using some form of tube mock-up tool, a better idea IMO is to just buy an extra J-bend & sacrifice it (by chopping it up giving you various lengths of straights & bend angles) to use as mock-up tools.

About the only "header making tool" I have ever found that really does help is using a simple hose clamp to align the weld joint between two pieces of header tubing before you tack them. Just take a regular SS hose clamp & drill 3 or 4 holes around the band. The 3-4 holes don't need to be real big, just big enough to have enough room to get a the tiny tack welds in there.

DILLIGASDAVE- Posts : 2262

Join date : 2009-08-08

Location : Texas. pronounced "texASS"

Re: DIY Headers

Re: DIY Headers

gonna have to build some new fender exits for the 632 C head deal..... is it wrong that I look forward to this??

richter69- Posts : 13649

Join date : 2008-12-02

Age : 53

Location : In the winners circle

Re: DIY Headers

Re: DIY Headers

richter69 wrote:gonna have to build some new fender exits for the 632 C head deal..... is it wrong that I look forward to this??

Headers are our favorite things to build. Each one presents a new challenge.

whatbumper- Posts : 3024

Join date : 2009-11-11

Age : 43

Re: DIY Headers

Re: DIY Headers

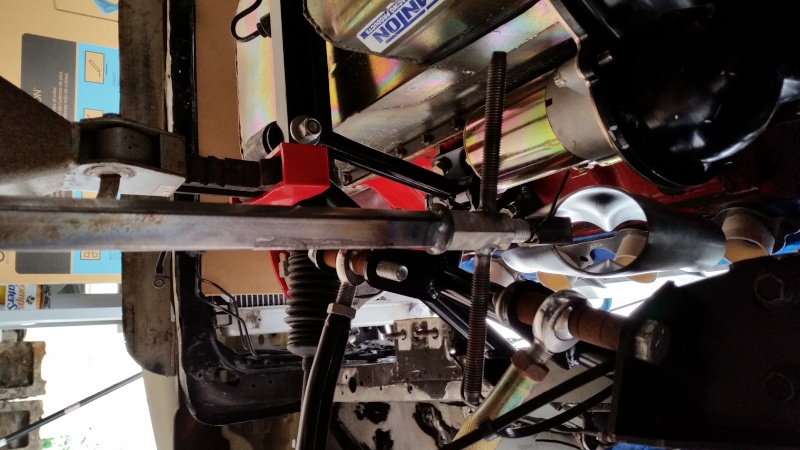

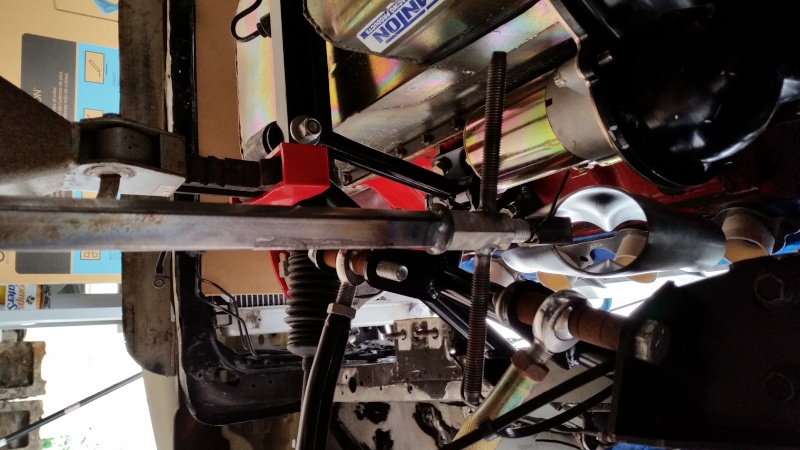

First of all - for a layman this process is time consuming and frustrating.

For a home mechanic I have ~20 hours into the mockup headers. 6 tubes to be precise. Pass completely mocked and 2 tubes on driver are in progress.

I choose to use an inline collector for max street clearance on a lowered car. There were significantly more bends when I tried mockup with a traditional collector.

Mockup of collector in the car:

Top view of mockup:

https://i.servimg.com/u/f18/19/29/35/79/20150812.jpg

Starting the process: MOTHER F*ing PROCESS! BASTAGES

https://i.servimg.com/u/f18/19/29/35/79/20150813.jpg

Mocked up (tacked passenger side): PS. Flanging the tubes with even a partial bend is and absolute nightmare. Tubes are not fully molded not is anything fully welded. My intent is to flare the tubes fully and tack weld the exterior more. The tig the inside tubes. Once completed mount a spare head to the welding table and fully secure flange to head and burn in outside.

https://i.servimg.com/u/f18/19/29/35/79/20150814.jpg

Driver side to crappy to show yet...

BTW - these are 1 7/8 to 2.5" collector. I will immediately transition to 3" for the x pipe.

Try not to laugh to hard. -Joe

For a home mechanic I have ~20 hours into the mockup headers. 6 tubes to be precise. Pass completely mocked and 2 tubes on driver are in progress.

I choose to use an inline collector for max street clearance on a lowered car. There were significantly more bends when I tried mockup with a traditional collector.

Mockup of collector in the car:

Top view of mockup:

https://i.servimg.com/u/f18/19/29/35/79/20150812.jpg

Starting the process: MOTHER F*ing PROCESS! BASTAGES

https://i.servimg.com/u/f18/19/29/35/79/20150813.jpg

Mocked up (tacked passenger side): PS. Flanging the tubes with even a partial bend is and absolute nightmare. Tubes are not fully molded not is anything fully welded. My intent is to flare the tubes fully and tack weld the exterior more. The tig the inside tubes. Once completed mount a spare head to the welding table and fully secure flange to head and burn in outside.

https://i.servimg.com/u/f18/19/29/35/79/20150814.jpg

Driver side to crappy to show yet...

BTW - these are 1 7/8 to 2.5" collector. I will immediately transition to 3" for the x pipe.

Try not to laugh to hard. -Joe

MustangBBF- Posts : 36

Join date : 2015-06-10

Re: DIY Headers

Re: DIY Headers

Well, that's an interesting idea. I like it.

Jess

Jess

Mustang-junky- Posts : 438

Join date : 2011-12-04

Location : Central New York. The state, not the city.

Re: DIY Headers

Re: DIY Headers

Never be afraid of failure with something you can do again................No Guts No Glory.

airford1- Posts : 192

Join date : 2009-10-15

Re: DIY Headers

Re: DIY Headers

Very true, thank you for that.

When I started this I definitely did not have this picture in my head. After starting this process I ended up here.

Not pretty or completed yet but they will get the exhaust out.

When I started this I definitely did not have this picture in my head. After starting this process I ended up here.

Not pretty or completed yet but they will get the exhaust out.

MustangBBF- Posts : 36

Join date : 2015-06-10

Page 1 of 2 • 1, 2

Similar topics

Similar topics» Full length zoomie headers vs collector headers

» Headers

» Headers

» headers

» C460 headers, possibly a460 too

» Headers

» Headers

» headers

» C460 headers, possibly a460 too

Page 1 of 2

Permissions in this forum:

You cannot reply to topics in this forum|

|

|