Still overheating - Water Pump bypass hose?

+3

rmcomprandy

supervel45

bigblockfordfxstb

7 posters

Page 1 of 4

Page 1 of 4 • 1, 2, 3, 4

Still overheating - Water Pump bypass hose?

Still overheating - Water Pump bypass hose?

Been some time from orignal posts about overheating issues and still no light at the end of the tunnel ...

Apart from the old clapper starter packing it in still like to resolve heating issue.

Motor

Early like 70 cast block - 40', cast heads, cam , pistons, intake, C6 - nothing crazy -

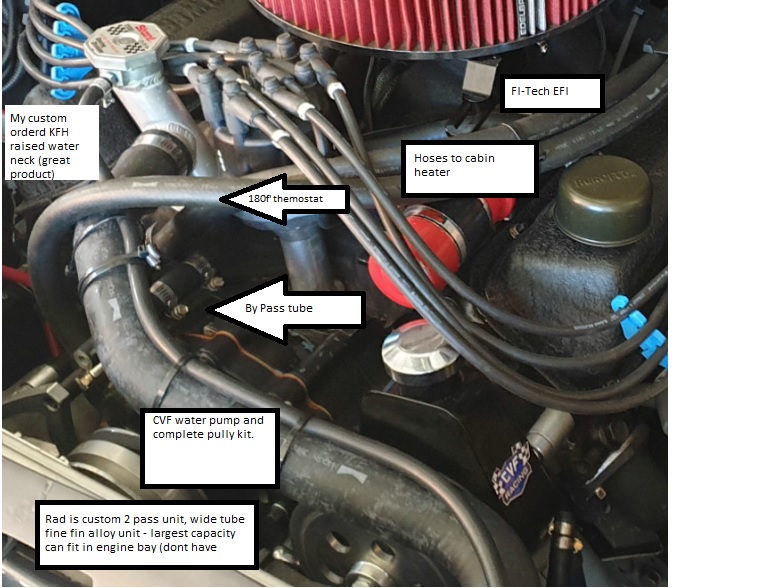

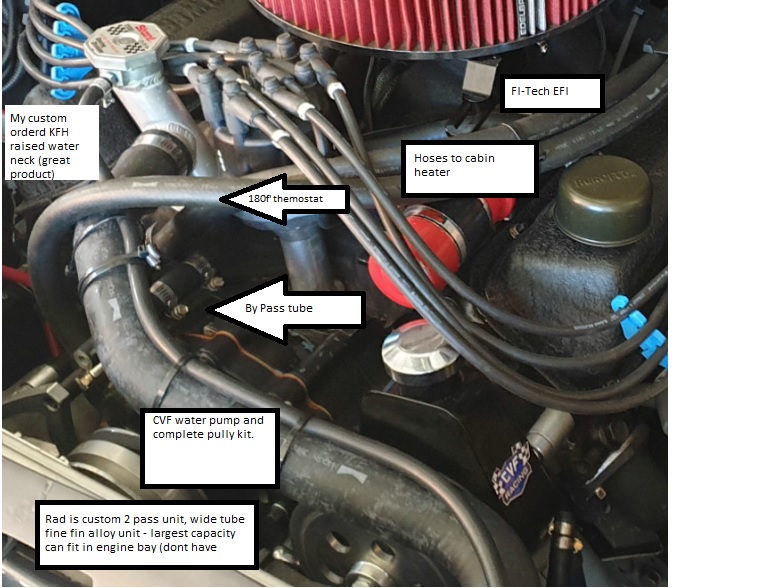

EDL AIRGAP intake - Fitech EFI - (good for starting and tracking fuel / air ratios)

has like 200F therostat , hiflow (think it was stant unit)

Running Redline Water wetter coolant

CVF Water pump and all pulley kit matched from them

Alloy Custom Rad - 2 x pass unit - largest capacity to fit in bay

Has 2 x electric high flow 16" and 14" fans behind radiator - if stopped they will bring the temp right down - but kill battery as constantly going when low speed as temp above the 210 - 215+

NO ROOM for MECH FAN

Hi Amp alternator low rpm pully - large guage feed.....

Have tested thermostant in boiling water and tried number of different models.

Bottom water hose is like new, so does not suck shut under RPM

Has place behind water pump :-)

Head gaskets on correct way (found out engine builder before screwed this up)

This is Australian Ford CAR and never came with this engine - Engine bay VERY tight - have seen other conversions same car no over heating type issues.

Low Speed / traffic - TEMP is heading north of 212 - 220 F

Only on motorway 50+mph does the temp settle back to 195- 200

Soon as you slow down to say 30 mph > 20 mph (or slow) the temp ramps straight upto 215 - 220 plus and the fans kick in trying to get it back down and they slow down after some time from batt drain....

Q: What is acceptable temp for normal driving - as said - pump gas - mild cam.

Q: Would blocking off the BY-PASS between manifold and pump help cooling to force it to go via the Radiator and not circle around block , even if themostat is I guess open at this temp ???

Q: Do I need to like drill holes in thermostat , or simply like cut center out of thermostant ??

Q: Timing - Can adjust with Fi-tech - been over various setting could it be running 2 advance or re-tarted - dont have pinging issues will get timings and rpm later from logs...

Have been over this a number of times like air pockets, (hence the KFH thermostant housing) -

mega thank you in advance ---- !!!! would really like to be able to drive the car without being concerned over constantly overheating.

Apart from the old clapper starter packing it in still like to resolve heating issue.

Motor

Early like 70 cast block - 40', cast heads, cam , pistons, intake, C6 - nothing crazy -

EDL AIRGAP intake - Fitech EFI - (good for starting and tracking fuel / air ratios)

has like 200F therostat , hiflow (think it was stant unit)

Running Redline Water wetter coolant

CVF Water pump and all pulley kit matched from them

Alloy Custom Rad - 2 x pass unit - largest capacity to fit in bay

Has 2 x electric high flow 16" and 14" fans behind radiator - if stopped they will bring the temp right down - but kill battery as constantly going when low speed as temp above the 210 - 215+

NO ROOM for MECH FAN

Hi Amp alternator low rpm pully - large guage feed.....

Have tested thermostant in boiling water and tried number of different models.

Bottom water hose is like new, so does not suck shut under RPM

Has place behind water pump :-)

Head gaskets on correct way (found out engine builder before screwed this up)

This is Australian Ford CAR and never came with this engine - Engine bay VERY tight - have seen other conversions same car no over heating type issues.

Low Speed / traffic - TEMP is heading north of 212 - 220 F

Only on motorway 50+mph does the temp settle back to 195- 200

Soon as you slow down to say 30 mph > 20 mph (or slow) the temp ramps straight upto 215 - 220 plus and the fans kick in trying to get it back down and they slow down after some time from batt drain....

Q: What is acceptable temp for normal driving - as said - pump gas - mild cam.

Q: Would blocking off the BY-PASS between manifold and pump help cooling to force it to go via the Radiator and not circle around block , even if themostat is I guess open at this temp ???

Q: Do I need to like drill holes in thermostat , or simply like cut center out of thermostant ??

Q: Timing - Can adjust with Fi-tech - been over various setting could it be running 2 advance or re-tarted - dont have pinging issues will get timings and rpm later from logs...

Have been over this a number of times like air pockets, (hence the KFH thermostant housing) -

mega thank you in advance ---- !!!! would really like to be able to drive the car without being concerned over constantly overheating.

Last edited by bigblockfordfxstb on June 5th 2023, 9:21 am; edited 2 times in total (Reason for editing : trying to get image to upload -- think I recall some trick to this :-()

bigblockfordfxstb- Posts : 125

Join date : 2015-06-22

Location : Australia

Re: Still overheating - Water Pump bypass hose?

Re: Still overheating - Water Pump bypass hose?

Why don't you try a 160 Degree Stat First and see if it helps?

Can you lose the underdrive pulleys. Might kill two Birds with one Stone. The charging issue and water pump speed.

You might also look into Ducting the Radiator further. Here's a quick primer.

https://www.youtube.com/watch?v=Fnmc_uJv54w

Can you lose the underdrive pulleys. Might kill two Birds with one Stone. The charging issue and water pump speed.

You might also look into Ducting the Radiator further. Here's a quick primer.

https://www.youtube.com/watch?v=Fnmc_uJv54w

supervel45- Posts : 4487

Join date : 2013-09-04

Re: Still overheating - Water Pump bypass hose?

Re: Still overheating - Water Pump bypass hose?

bigblockfordfxstb wrote:Been some time from orignal posts about overheating issues and still no light at the end of the tunnel ...

Apart from the old clapper starter packing it in still like to resolve heating issue.

Motor

Early like 70 cast block - 40', cast heads, cam , pistons, intake, C6 - nothing crazy -

EDL AIRGAP intake - Fitech EFI - (good for starting and tracking fuel / air ratios)

has like 200F therostat , hiflow (think it was stant unit)

Running Redline Water wetter coolant

CVF Water pump and all pulley kit matched from them

Alloy Custom Rad - 2 x pass unit - largest capacity to fit in bay

Has 2 x electric high flow 16" and 14" fans behind radiator - if stopped they will bring the temp right down - but kill battery as constantly going when low speed as temp above the 210 - 215+

NO ROOM for MECH FAN

Hi Amp alternator low rpm pully - large guage feed.....

Have tested thermostant in boiling water and tried number of different models.

Bottom water hose is like new, so does not suck shut under RPM

Has place behind water pump :-)

Head gaskets on correct way (found out engine builder before screwed this up)

This is Australian Ford CAR and never came with this engine - Engine bay VERY tight - have seen other conversions same car no over heating type issues.

Low Speed / traffic - TEMP is heading north of 212 - 220 F

Only on motorway 50+mph does the temp settle back to 195- 200

Soon as you slow down to say 30 mph > 20 mph (or slow) the temp ramps straight upto 215 - 220 plus and the fans kick in trying to get it back down and they slow down after some time from batt drain....

Q: What is acceptable temp for normal driving - as said - pump gas - mild cam.

Q: Would blocking off the BY-PASS between manifold and pump help cooling to force it to go via the Radiator and not circle around block , even if themostat is I guess open at this temp ???

Q: Do I need to like drill holes in thermostat , or simply like cut center out of thermostant ??

Q: Timing - Can adjust with Fi-tech - been over various setting could it be running 2 advance or re-tarted - dont have pinging issues will get timings and rpm later from logs...

Have been over this a number of times like air pockets, (hence the KFH thermostant housing) -

mega thank you in advance ---- !!!! would really like to be able to drive the car without being concerned over constantly overheating.

1. I would like 200 degree's are less. 220 is pretty high, new cars run that now though.

What are the Operating Ambient Temperatures, when it Overheats?

2. Don't know. Never heard of anyone doing it before either.

3. You can drill one to three 1/8" holes or more and it/they will lower the temperature of the T-Stat accordingly. One hole will make a Non Failsafe T-Stat into a Failsafe one. I would not cut the whole center out. They make restrictors to replace the T-Stat in different sizes Also.

4. Yes Timing Changes can Help with running temperature. Usually a little more advance can help, if it's running retarded. It's one of those it all depends deals.

supervel45- Posts : 4487

Join date : 2013-09-04

Re: Still overheating - Water Pump bypass hose?

Re: Still overheating - Water Pump bypass hose?

bigblockfordfxstb wrote:Been some time from orignal posts about overheating issues and still no light at the end of the tunnel ...

Apart from the old clapper starter packing it in still like to resolve heating issue.

Motor

Early like 70 cast block - 40', cast heads, cam , pistons, intake, C6 - nothing crazy -

EDL AIRGAP intake - Fitech EFI - (good for starting and tracking fuel / air ratios)

has like 200F therostat , hiflow (think it was stant unit)

Running Redline Water wetter coolant

CVF Water pump and all pulley kit matched from them

Alloy Custom Rad - 2 x pass unit - largest capacity to fit in bay

Has 2 x electric high flow 16" and 14" fans behind radiator - if stopped they will bring the temp right down - but kill battery as constantly going when low speed as temp above the 210 - 215+

NO ROOM for MECH FAN

Hi Amp alternator low rpm pully - large guage feed.....

Have tested thermostant in boiling water and tried number of different models.

Bottom water hose is like new, so does not suck shut under RPM

Has place behind water pump :-)

Head gaskets on correct way (found out engine builder before screwed this up)

This is Australian Ford CAR and never came with this engine - Engine bay VERY tight - have seen other conversions same car no over heating type issues.

Low Speed / traffic - TEMP is heading north of 212 - 220 F

Only on motorway 50+mph does the temp settle back to 195- 200

Soon as you slow down to say 30 mph > 20 mph (or slow) the temp ramps straight upto 215 - 220 plus and the fans kick in trying to get it back down and they slow down after some time from batt drain....

Q: What is acceptable temp for normal driving - as said - pump gas - mild cam.

Q: Would blocking off the BY-PASS between manifold and pump help cooling to force it to go via the Radiator and not circle around block , even if themostat is I guess open at this temp ???

Q: Do I need to like drill holes in thermostat , or simply like cut center out of thermostant ??

Q: Timing - Can adjust with Fi-tech - been over various setting could it be running 2 advance or re-tarted - dont have pinging issues will get timings and rpm later from logs...

Have been over this a number of times like air pockets, (hence the KFH thermostant housing) -

mega thank you in advance ---- !!!! would really like to be able to drive the car without being concerned over constantly overheating.

Water flow not enough through system with not enough pressure head in the block at low speed.

Make the water pump go faster or get a different pump which will flow better at LOW speeds; not more at higher RPM.

"FlowKooler" pumps work the best for street running.

Oh year, most new car O.E.M. electric fans don't even start until about 218 degrees.

Mark Miller likes this post

Re: Still overheating - Water Pump bypass hose?

Re: Still overheating - Water Pump bypass hose?

Here's my .02 from my experience with overheating (and tight engine compartments). You don't have a coolant flow problem at speed, so your pump is fine. Heating up at low speed can be 2 things... normally it's insufficient flow through the radiator, but with a 200 thermostat it's hard to tell. The fact you have a tight engine compartment makes me suggest 2 things.

Ditch the 200 thermostat. Odds are your engine isn't machined for the tolerances a newer engine is, so go with a 180. I always drill an 1/8" hole in the thermostat to provide some limited flow past it.

After changing the thermostat, take off the hood. Yes, the hood. People seem to drill in on coolant flow to cure overheating, but if the air going through the radiator can't escape, it won't cool efficiently. A shroud covering the whole radiator core would help as well, but sounds like you don't have the room. You may consider re-doing your fan arrangement because you want SHROUDED CFM, not just flow over a limited core surface area.

Hope you see positive results!

Ditch the 200 thermostat. Odds are your engine isn't machined for the tolerances a newer engine is, so go with a 180. I always drill an 1/8" hole in the thermostat to provide some limited flow past it.

After changing the thermostat, take off the hood. Yes, the hood. People seem to drill in on coolant flow to cure overheating, but if the air going through the radiator can't escape, it won't cool efficiently. A shroud covering the whole radiator core would help as well, but sounds like you don't have the room. You may consider re-doing your fan arrangement because you want SHROUDED CFM, not just flow over a limited core surface area.

Hope you see positive results!

Slowride- Posts : 32

Join date : 2017-11-08

bigblockfordfxstb likes this post

Re: Still overheating - Water Pump bypass hose?

Re: Still overheating - Water Pump bypass hose?

^No Doubt about Getting the Heat Out of the Engine Compartment, as well as the rest of that.

It would be nice if he said what the outside temperature was, it gets hot Down Under in the Summer.

Sounds like a New Bigger Battery Might Help some too.

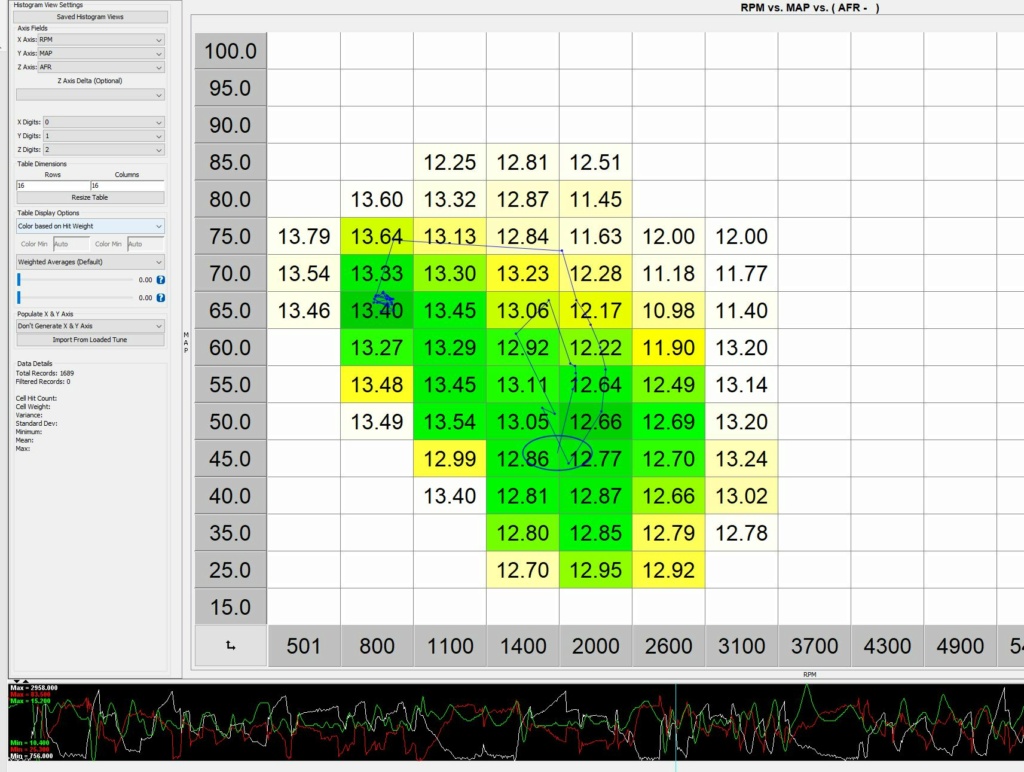

What Cruise Air Fuel Ratio and Timing are you Running Now? What Compression Ratio?

It would be nice if he said what the outside temperature was, it gets hot Down Under in the Summer.

Sounds like a New Bigger Battery Might Help some too.

What Cruise Air Fuel Ratio and Timing are you Running Now? What Compression Ratio?

supervel45- Posts : 4487

Join date : 2013-09-04

bigblockfordfxstb likes this post

Re: Still overheating - Water Pump bypass hose?

Re: Still overheating - Water Pump bypass hose?

Slowride wrote:Here's my .02 from my experience with overheating (and tight engine compartments). You don't have a coolant flow problem at speed, so your pump is fine. Heating up at low speed can be 2 things... normally it's insufficient flow through the radiator, but with a 200 thermostat it's hard to tell. The fact you have a tight engine compartment makes me suggest 2 things.

Ditch the 200 thermostat. Odds are your engine isn't machined for the tolerances a newer engine is, so go with a 180. I always drill an 1/8" hole in the thermostat to provide some limited flow past it.

After changing the thermostat, take off the hood. Yes, the hood. People seem to drill in on coolant flow to cure overheating, but if the air going through the radiator can't escape, it won't cool efficiently. A shroud covering the whole radiator core would help as well, but sounds like you don't have the room. You may consider re-doing your fan arrangement because you want SHROUDED CFM, not just flow over a limited core surface area.

Hope you see positive results!

TThanks for tip - Agree that at low speed could be air flow through radiator but it feels like it just gets hot fast soon as I slow down and at idle, the fans are just almost always on. (fans a triggered to come on at 219f and 213f) Fans have shroud.

I will try lower thermostat and hole (think I tried various things before) but still wanted to know, does that host between the intake and pump act as a by-pass for the rad and if I block them, and say open thermostat does that force all water through radiator and not circulate around block.

On cool day here (no humidity) around 68 still runs HOT HOT after some time you can see oil pressure lower had idle as everything is just heat soaked.

*note from other comments - I have a small pulley on high amp alternator so at low speed also feeds the battery to keeps electric fans going ( I did a pully calculation to the ALT power curve, so comes start above idle and safe to 6000RPM)

Block has been tanked and cleaned (block is not full of rust etc)

The V-Belt - pulley kit and Water pump is from CVF Ive have been in touch with them a few times and they have sold a shed loads of kits, not heard of same issue.

Water pump from them is High Flow with like waterwheel style on back to... (if that’s the right name) and yes I have the plate in place.

Had these written down from what I think are more old measurements on pulley and worked with CVF and the ratio is very small difference - (cvf) 1.09 vs 1.19 (stock)

Waterpump

CVF Diameter: 5.2" - 132.08mm 1.09

OLD ?? Measured 6.2" - 160mm 1.19

Crank

CVF - 5.7" - 144.78mm

OLD ?? Measured 7.48" - 190mm

CVF

Belt Length 833

Ratio 1 : 1.09

RPM Small 1090.9

RPM Large 1000

Belt Speed 452.4 m / min

Stock

Belt Length 951

Ratio 1 : 1.19

RPM Small 1187.5

RPM Large 1000

Belt Speed 596.9 m / min

I have sealed around the radiator etc to make sure any air making its way to the rad passes and not around, I may try seal the bottom between the bottom of the rad and splitter (bottom of front bar), but not sure if this could cause more an air dam like turbulence .

I will try raise the back to the bonnet to let more air out - or like mentioned in other comment remove it totally to see what happens....

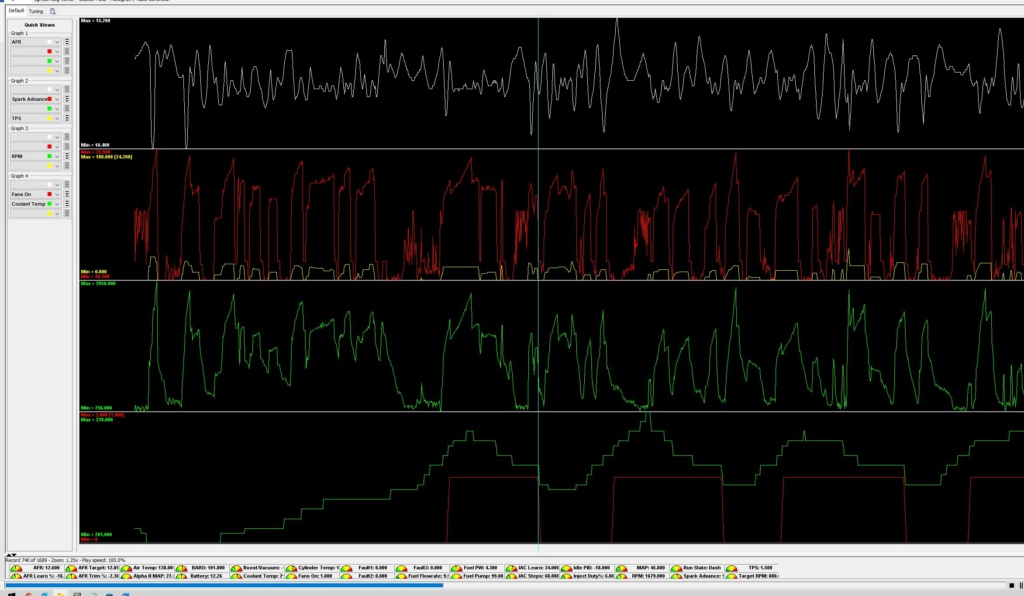

As for Fuel / Air / Timing / RPM ill have to manually put some figures down, im using megalog viewer from the FI-TECH , this is low RRP not really going over 2500-3000RPM at any point just cruzing and slowing down - temp quickly rises and fans on..... but hot MAX 228f

bigblockfordfxstb- Posts : 125

Join date : 2015-06-22

Location : Australia

Re: Still overheating - Water Pump bypass hose?

Re: Still overheating - Water Pump bypass hose?

Don't dwell on the bypass too much. It circulates coolant before the thermostat opens and keeps from deadheading the water pump until the thermostat opens. Remember, a thermostat isn't a static on/off device, it's purpose is to maintain a temp by opening AND CLOSING. There really isn't a lot of volume going through the bypass (5/8" hose vs 1-1/2" top hose).bigblockfordfxstb wrote:

I will try lower thermostat and hole (think I tried various things before) but still wanted to know, does that host between the intake and pump act as a by-pass for the rad and if I block them, and say open thermostat does that force all water through radiator and not circulate around block.

Are you able to change the on/off temps for your fans or is it a fixed temp switch?

Slowride- Posts : 32

Join date : 2017-11-08

Re: Still overheating - Water Pump bypass hose?

Re: Still overheating - Water Pump bypass hose?

Will the alternator put out for 14.5 volts or close to it at idle, cold?

Check the out put voltage on a cold startup vs. engine at max temp. and see if it drops much, with fans on vs off. If you can't maintain over 13 volts, Hot, it's will struggle to charge quickly on short drives and is not operating properly, if the system is sized Correctly, Including pulley speed at idle and off idle.

Do a load test on your battery, from a full charge also to check it's condition.

Water pump pulley ratio looks pretty good.

I would try a 160 T-Stat and try bringing the fans on 40F sooner. At least you can start your heat soak creep lower that way and it may not get out of hand as fast.

On the A/F and cruise timing I would try for somewhere in the 14's and 36-44 total depending on the load/weight/compression/gear ratio ect. You guys I believe have 98 octane so you should not have to worry about detonation as much, with your timing curve/total cruise timing.

Try the hood open trick but, if you don't run with the hood off or install a cowl hood, then it's just an indicator, not a fix.

I don't think removing the bypass is a good idea or a fix for your problem either.

Are you funning and external transmission cooler? How High is the Stall Speed? What rear end gear ratio?

Check the out put voltage on a cold startup vs. engine at max temp. and see if it drops much, with fans on vs off. If you can't maintain over 13 volts, Hot, it's will struggle to charge quickly on short drives and is not operating properly, if the system is sized Correctly, Including pulley speed at idle and off idle.

Do a load test on your battery, from a full charge also to check it's condition.

Water pump pulley ratio looks pretty good.

I would try a 160 T-Stat and try bringing the fans on 40F sooner. At least you can start your heat soak creep lower that way and it may not get out of hand as fast.

On the A/F and cruise timing I would try for somewhere in the 14's and 36-44 total depending on the load/weight/compression/gear ratio ect. You guys I believe have 98 octane so you should not have to worry about detonation as much, with your timing curve/total cruise timing.

Try the hood open trick but, if you don't run with the hood off or install a cowl hood, then it's just an indicator, not a fix.

I don't think removing the bypass is a good idea or a fix for your problem either.

Are you funning and external transmission cooler? How High is the Stall Speed? What rear end gear ratio?

supervel45- Posts : 4487

Join date : 2013-09-04

Re: Still overheating - Water Pump bypass hose?

Re: Still overheating - Water Pump bypass hose?

Slowride wrote:Don't dwell on the bypass too much. It circulates coolant before the thermostat opens and keeps from deadheading the water pump until the thermostat opens. Remember, a thermostat isn't a static on/off device, it's purpose is to maintain a temp by opening AND CLOSING. There really isn't a lot of volume going through the bypass (5/8" hose vs 1-1/2" top hose).bigblockfordfxstb wrote:

I will try lower thermostat and hole (think I tried various things before) but still wanted to know, does that host between the intake and pump act as a by-pass for the rad and if I block them, and say open thermostat does that force all water through radiator and not circulate around block.

Are you able to change the on/off temps for your fans or is it a fixed temp switch?

thanks for info, I control fans with Fitech , off / on at desired temp...

reason for setting it current temp was if lower it was constantly on, unless doing like over 55mph / 2000rpm for a period of time, I'll go over more of my temp logs but quite sure after say 10min of the car starting the thermostat opens and never closes as it's always hot unless cruising over 45 -50mph soon as I slow down for any traffic or lights, the temp climbs and fans are just on.

bigblockfordfxstb- Posts : 125

Join date : 2015-06-22

Location : Australia

Re: Still overheating - Water Pump bypass hose?

Re: Still overheating - Water Pump bypass hose?

bigblockfordfxstb wrote:Been some time from orignal posts about overheating issues and still no light at the end of the tunnel ...

If you have a heater core that is not shut off by a valve, that is supposed to shut it off only when the AC is running, you can remover the bypass hose, and the heater core will prevent deadheading the water pump.

I have a 460 in a 76 Montego wagon; 4K#, plus a small camp trailer. Over heat is marginal at best, and at 100+ ambient in the SoCal desert, just about un-driveable.

The widest opening thermostat I am aware of equates to a three quarter round tube. So why do we have two inch hoses? For a year I have been running a wider opening stat; no stat at all. Thermostats are actually a new thing in cars. My stock 48 flathead did not have any. Try it.

RayDav- Posts : 26

Join date : 2016-10-03

Re: Still overheating - Water Pump bypass hose?

Re: Still overheating - Water Pump bypass hose?

^ Because Themodynamic's and Math. ^ So it worked in your case?

Here's one on the Air Side. Too lazy to look for one in the water side. Water has to stay in the Heat Exchanger the Right amount of Time for the Air to have Maximum Cooling Effect.

https://www.govinfo.gov/content/pkg/GOVPUB-C13-f76f70c9a5ab20575156de71c955da73/pdf/GOVPUB-C13-f76f70c9a5ab20575156de71c955da73.pdf

The Fans Have to Run at Low Speed in the Real World unless it is Very Low Ambient Conditions, even 68F. The Temperature will always Climb Coming off a Highway into traffic or a Red Light Too.

In Laymans terms, on thermostat or block restrictors, whatever amount of water restriction through the engine, that gives the greatest DeltaT drop across the radiator will be the most efficient, as a general rule. IE Widest temperature spit between the upper and lower hose.

If you don't have sensors that you can monitor driving on both hoses, it's just knowledge to file away, and use trial and error.

Have you calibrated your temp sensor/gauge with a known good thermometer in the radiator? Never Trust a Gauge or Sensor to be Accurate.

These other cars with the same Combo, are you sure they are the same and perform as you think?

Here's one on the Air Side. Too lazy to look for one in the water side. Water has to stay in the Heat Exchanger the Right amount of Time for the Air to have Maximum Cooling Effect.

https://www.govinfo.gov/content/pkg/GOVPUB-C13-f76f70c9a5ab20575156de71c955da73/pdf/GOVPUB-C13-f76f70c9a5ab20575156de71c955da73.pdf

The Fans Have to Run at Low Speed in the Real World unless it is Very Low Ambient Conditions, even 68F. The Temperature will always Climb Coming off a Highway into traffic or a Red Light Too.

In Laymans terms, on thermostat or block restrictors, whatever amount of water restriction through the engine, that gives the greatest DeltaT drop across the radiator will be the most efficient, as a general rule. IE Widest temperature spit between the upper and lower hose.

If you don't have sensors that you can monitor driving on both hoses, it's just knowledge to file away, and use trial and error.

Have you calibrated your temp sensor/gauge with a known good thermometer in the radiator? Never Trust a Gauge or Sensor to be Accurate.

These other cars with the same Combo, are you sure they are the same and perform as you think?

supervel45- Posts : 4487

Join date : 2013-09-04

Re: Still overheating - Water Pump bypass hose?

Re: Still overheating - Water Pump bypass hose?

I guess I'll step in on this because I spent most of my working life with centrifugal pump design and solutions as a mechanical engineer working directly with fluid flow problems.

It looks like low RPM coolant flow is insufficient or the radiator size/capacity is too small.

I spent some time on the CVF website tying to see if their pump is different from the factory but could not determine their high flow claim being better than factory pumps. I do know that there are flat back plates and plates that are stamped to provide more space with the pump impeller. The plate with the recess should be used when a pump impeller protrudes from the housing machined surface. If the impeller is below the machined surface and the recessed plate is used. Impeller clearance will be large and internal leakage will be great. I think the impeller has the shroud on the side of the pulley so plate to impeller clearance is vital to pump performance. If the impeller is flush with the machining. Then the gasket will provide the proper clearance. Impeller to plate clearance at .030" is optimal.

What makes a high flow pump? The answer comes from the impeller flow channel width or deeper vanes on the impeller.

Higher pressure comes from a larger impeller diameter.

The pulley ratios that you provided indicate that the CVF pump runs 10% slower than factory. A general rule for centrifugal pumps is that the flow will vary linearly with rotational speed change. And the pressure differential will vary by the square of the speed change.

If the performance of the CVF pump is equal to the factory pump. The flow is 10% lower and the pressure differential is 19% lower. Assuming this lower performance and knowing that the actual flow rate occurs where the pump flow curve crosses the system curve from the engine and radiator. If we can reduce the system differential curve then overall flow will go up. one way that you can accomplish this is by using a high flow thermostat or using a washer orifice in place of the stat. This reduces system loss curve which leads to higher flow rate. You can also take a stat and cutout the entire working parts to make the restriction lower.

The bypass is there to stop an air lock and a no flow condition when the stat is closed. When there isnt a stat the bypass isnt needed as the flow loop is free flowing. But in all cases the bypass directly allows flow to bypass the radiator and flow back into the block.

Sorry for being long winded here.

It looks like low RPM coolant flow is insufficient or the radiator size/capacity is too small.

I spent some time on the CVF website tying to see if their pump is different from the factory but could not determine their high flow claim being better than factory pumps. I do know that there are flat back plates and plates that are stamped to provide more space with the pump impeller. The plate with the recess should be used when a pump impeller protrudes from the housing machined surface. If the impeller is below the machined surface and the recessed plate is used. Impeller clearance will be large and internal leakage will be great. I think the impeller has the shroud on the side of the pulley so plate to impeller clearance is vital to pump performance. If the impeller is flush with the machining. Then the gasket will provide the proper clearance. Impeller to plate clearance at .030" is optimal.

What makes a high flow pump? The answer comes from the impeller flow channel width or deeper vanes on the impeller.

Higher pressure comes from a larger impeller diameter.

The pulley ratios that you provided indicate that the CVF pump runs 10% slower than factory. A general rule for centrifugal pumps is that the flow will vary linearly with rotational speed change. And the pressure differential will vary by the square of the speed change.

If the performance of the CVF pump is equal to the factory pump. The flow is 10% lower and the pressure differential is 19% lower. Assuming this lower performance and knowing that the actual flow rate occurs where the pump flow curve crosses the system curve from the engine and radiator. If we can reduce the system differential curve then overall flow will go up. one way that you can accomplish this is by using a high flow thermostat or using a washer orifice in place of the stat. This reduces system loss curve which leads to higher flow rate. You can also take a stat and cutout the entire working parts to make the restriction lower.

The bypass is there to stop an air lock and a no flow condition when the stat is closed. When there isnt a stat the bypass isnt needed as the flow loop is free flowing. But in all cases the bypass directly allows flow to bypass the radiator and flow back into the block.

Sorry for being long winded here.

Dave De- Posts : 791

Join date : 2011-05-27

Location : Highland, MI

rmcomprandy likes this post

Re: Still overheating - Water Pump bypass hose?

Re: Still overheating - Water Pump bypass hose?

^ When you said Gasket Dave, this popped into my head. Could this do it, if the Gaskets were wrong also?

https://www.460ford.com/threads/water-pump-back-plate-gaskets.143812/

https://www.460ford.com/threads/water-pump-back-plate-gaskets.143812/

supervel45- Posts : 4487

Join date : 2013-09-04

Re: Still overheating - Water Pump bypass hose?

Re: Still overheating - Water Pump bypass hose?

Yes, the wrong gasket is possible but the wrong plate is a definite performance problem. It looks like most performance mechanical pumps use the plate with the recess to keep the impeller tip clearance close. Search for the M-8501-460BP plate. If the flat plate is used tip clearance will be very high and pump performance will be poor with a lower pressure/flow curve that will result reduced flow. In any case just look at the impeller clearance for your parts to be be around .030" (.8mm)

Dave De- Posts : 791

Join date : 2011-05-27

Location : Highland, MI

Re: Still overheating - Water Pump bypass hose?

Re: Still overheating - Water Pump bypass hose?

In my experience stock pumps have stamped steel impellers, so the vanes are open to the rear, and rear spacing is critical. Aftermarket pumps have cast - and possibly machined - impellers, and the vanes face forward, so rear spacing is not critical.

RayDav- Posts : 26

Join date : 2016-10-03

Re: Still overheating - Water Pump bypass hose?

Re: Still overheating - Water Pump bypass hose?

I take it, it's this CVF?

https://www.cvfracing.com/black-ford-429-460-mechanical-water-pump-high-flow-aluminum/?gclid=CjwKCAjwyqWkBhBMEiwAp2yUFi2R76erEFw6HjUjpq0Zxkl2lFqSHXPuH4FPRTuow4Q4TSn8vTmbTRoC-E4QAvD_BwE

They don't show a shot of the CVF impeller that I saw or say how many blades it has.

When I was looking for spec's and pump ratings, I came across this old thread. It was interesting. Not a lot of GPM ratings at Different RPMS to be found on the various pumps.

https://www.460ford.com/threads/flowkooler-high-flow-pump-better-then-pro-comp.181361/

Here's a nice shot of the Highly Recommended Flow Coolers 16 Blade Impeller.

https://flowkoolerwaterpumps.com/products/1645-1995-1997-ford-big-block-460-water-pump

That CVF might be like the Edelbrock and more suited for higher speed operation? If they threw the backing plate in with their pumps it would sure make life simpler. Have fun with it all.

PS: If anyone comes across this later, watch the part numbers on 429/460. FlowKooler has several models.

https://flowkoolerwaterpumps.com/collections/all/products/1651-1970-1992-ford-429-460-water-pump

https://www.cvfracing.com/black-ford-429-460-mechanical-water-pump-high-flow-aluminum/?gclid=CjwKCAjwyqWkBhBMEiwAp2yUFi2R76erEFw6HjUjpq0Zxkl2lFqSHXPuH4FPRTuow4Q4TSn8vTmbTRoC-E4QAvD_BwE

They don't show a shot of the CVF impeller that I saw or say how many blades it has.

When I was looking for spec's and pump ratings, I came across this old thread. It was interesting. Not a lot of GPM ratings at Different RPMS to be found on the various pumps.

https://www.460ford.com/threads/flowkooler-high-flow-pump-better-then-pro-comp.181361/

Here's a nice shot of the Highly Recommended Flow Coolers 16 Blade Impeller.

https://flowkoolerwaterpumps.com/products/1645-1995-1997-ford-big-block-460-water-pump

That CVF might be like the Edelbrock and more suited for higher speed operation? If they threw the backing plate in with their pumps it would sure make life simpler. Have fun with it all.

PS: If anyone comes across this later, watch the part numbers on 429/460. FlowKooler has several models.

https://flowkoolerwaterpumps.com/collections/all/products/1651-1970-1992-ford-429-460-water-pump

supervel45- Posts : 4487

Join date : 2013-09-04

rmcomprandy likes this post

Re: Still overheating - Water Pump bypass hose?

Re: Still overheating - Water Pump bypass hose?

Sorry but I dont know how to reply to each of the comments and questions, only find a REPLY at the bottom of the page...

**** I have sent of an email to CVF if they have some more details around the pump, ie did they supply backing plate , if I then I just bought something from Summit at the time --- this is a response from them long time ago about the pump...

The pump you purchased is also an aluminum high flow model which is modeled after an Edelbrock unit, they tend to flow 20 - 30% better than stock units. The graph is really helpful. It looks like you there is just too much heat in the engine bay at idle. Are any of your coolant hoses near headers? The system you purchased is pretty bullet proof, but the data is compelling

@supervel45 Regarding ALT power output - voltages will check this again.

Also I found some PICs of the current thermostat and it was a 180F HIGH FLOW

@RayDav Regarding the heater core hoses, they I think are controlled via heater vacuum type switch currently disconnected, so it should be open for flow right ?? Also see PIC the thermostat stat I have "high flow" is 1.3" (33.6mm)

supervel45 I did initial testing of temp sender and thermostat to make sure they are what they should be - but the point of measuring the IN vs Out water temp would be good- just trying to work out best method for this either has to be in line hose or on outer of each hose if even possible ??? Also regarding gaskets - yes I recall 2 different gaskets I had a complete felpro kit, but cant recall if also got any with pump and or plate if it was ordered separately from memory. (I wonder if I can check my summit order history years back?)

Dave DE Thanks lots of info --- I have a high flow themostat , but wonder if like mentioned , cut the center of one out and also block the waterpump bypass ... As for the main point of the waterpump to backing plate - would not know without the removal of it all unless CVF reply back with all the details and if they did supply the plate or not?!!

**** I have sent of an email to CVF if they have some more details around the pump, ie did they supply backing plate , if I then I just bought something from Summit at the time --- this is a response from them long time ago about the pump...

The pump you purchased is also an aluminum high flow model which is modeled after an Edelbrock unit, they tend to flow 20 - 30% better than stock units. The graph is really helpful. It looks like you there is just too much heat in the engine bay at idle. Are any of your coolant hoses near headers? The system you purchased is pretty bullet proof, but the data is compelling

@supervel45 Regarding ALT power output - voltages will check this again.

Also I found some PICs of the current thermostat and it was a 180F HIGH FLOW

@RayDav Regarding the heater core hoses, they I think are controlled via heater vacuum type switch currently disconnected, so it should be open for flow right ?? Also see PIC the thermostat stat I have "high flow" is 1.3" (33.6mm)

supervel45 I did initial testing of temp sender and thermostat to make sure they are what they should be - but the point of measuring the IN vs Out water temp would be good- just trying to work out best method for this either has to be in line hose or on outer of each hose if even possible ??? Also regarding gaskets - yes I recall 2 different gaskets I had a complete felpro kit, but cant recall if also got any with pump and or plate if it was ordered separately from memory. (I wonder if I can check my summit order history years back?)

Dave DE Thanks lots of info --- I have a high flow themostat , but wonder if like mentioned , cut the center of one out and also block the waterpump bypass ... As for the main point of the waterpump to backing plate - would not know without the removal of it all unless CVF reply back with all the details and if they did supply the plate or not?!!

bigblockfordfxstb- Posts : 125

Join date : 2015-06-22

Location : Australia

Re: Still overheating - Water Pump bypass hose?

Re: Still overheating - Water Pump bypass hose?

supervel45 Sorry missed other items - Are you saying should be running leaner 14 at cruzing yes and Ill check timing again.... yes running TransCooler , stall is around 2000 , and rear is from memory is like 3.27 or 3.24 - sitting on 50mph is around 2000 or 2500 RPM --- Need write things down more.

bigblockfordfxstb- Posts : 125

Join date : 2015-06-22

Location : Australia

Re: Still overheating - Water Pump bypass hose?

Re: Still overheating - Water Pump bypass hose?

On the hose temperature you could use a laser thermometer when stationary. They do make Fluke strap on probes that could be run in the vehicle for mobile measurements. That kind of monitoring is used in stationary equipment all the time as well as engineering and Lab environments. For what your doing I would shoot for lowest operating temperature, and not get too hung up on it.

Your Email from the above post, Said, styled after an Edelbrock Unit. There have been a lot of people come through these forums and switch to the FlowKooler pumps and solve problems. Randy mentioned it at the beginning of this thread, and I did not Know the CVF Pump you have was like that. You can keep playing with it, and maybe you will make some headway on lowering you slow speed temps but it sure sounds like the pump style to me at this point.

With all that said it also sounds like you have a charging and or undersized/weak battery issue also. The alternator voltages will usually drop a little in high heat conditions from my experience, that's why I said to check it hot and cold with the fans both on and off.

Electric motors also start going bad all the time and drawing higher current too. That's why we always logged amp draws on inspection, to anticipate potential upcoming problems or current ones.

Your Email from the above post, Said, styled after an Edelbrock Unit. There have been a lot of people come through these forums and switch to the FlowKooler pumps and solve problems. Randy mentioned it at the beginning of this thread, and I did not Know the CVF Pump you have was like that. You can keep playing with it, and maybe you will make some headway on lowering you slow speed temps but it sure sounds like the pump style to me at this point.

With all that said it also sounds like you have a charging and or undersized/weak battery issue also. The alternator voltages will usually drop a little in high heat conditions from my experience, that's why I said to check it hot and cold with the fans both on and off.

Electric motors also start going bad all the time and drawing higher current too. That's why we always logged amp draws on inspection, to anticipate potential upcoming problems or current ones.

supervel45- Posts : 4487

Join date : 2013-09-04

Re: Still overheating - Water Pump bypass hose?

Re: Still overheating - Water Pump bypass hose?

bigblockfordfxstb wrote:

supervel45 Sorry missed other items - Are you saying should be running leaner 14 at cruzing yes and Ill check timing again.... yes running TransCooler , stall is around 2000 , and rear is from memory is like 3.27 or 3.24 - sitting on 50mph is around 2000 or 2500 RPM --- Need write things down more.

The stall and gear sound OK to me, just wanted to make sure it was not out of whack like 2.75 and 4,500 riding the stall cruising. The remote trans cooler can take some load off the radiator and depending how it mounted can help.

I would play with A/F ratios all through the 14 to 14.7 range and timing up into the mid 40's and try do Data Log and see if it makes any improvement. I don't know what you have for a cam but if it's pretty mild I would shoot between 14 and 20 for idle timing.

That's a nice looking thermostat. When boiling it with Your thermometer, note the initial opening temp and the fully open temp. They do have different personalities form the ones I have done.

PS: Read what Randy Said in Post #5. Read a couple of more times. Also what he said about the Edelbrock backing Plates. They don't make these 429/460 non stock water pumps easy.

https://www.460ford.com/threads/water-pump-back-plate-gaskets.143812/

supervel45- Posts : 4487

Join date : 2013-09-04

Re: Still overheating - Water Pump bypass hose?

Re: Still overheating - Water Pump bypass hose?

supervel45 wrote:On the hose temperature you could use a laser thermometer when stationary. They do make Fluke strap on probes that could be run in the vehicle for mobile measurements. That kind of monitoring is used in stationary equipment all the time as well as engineering and Lab environments. For what your doing I would shoot for lowest operating temperature, and not get too hung up on it.

Your Email from the above post, Said, styled after an Edelbrock Unit. There have been a lot of people come through these forums and switch to the FlowKooler pumps and solve problems. Randy mentioned it at the beginning of this thread, and I did not Know the CVF Pump you have was like that. You can keep playing with it, and maybe you will make some headway on lowering you slow speed temps but it sure sounds like the pump style to me at this point.

With all that said it also sounds like you have a charging and or undersized/weak battery issue also. The alternator voltages will usually drop a little in high heat conditions from my experience, that's why I said to check it hot and cold with the fans both on and off.

Electric motors also start going bad all the time and drawing higher current too. That's why we always logged amp draws on inspection, to anticipate potential upcoming problems or current ones.

Morning here from Oz... why do you think anything to do with battery or charging is an issue? just curious was it something I mentioned ? I'll check this out I have multimeter for cold and clamp DC style meter also to see...

I do have a Lazer temp monitor, but thinking I have a bung near to rad outlet and possibly a spare temp place for sensor near thermostat and could buy 2 x cheap gauges to looking at this...

as for water pump, I'll see if CVF come back with and possibly look to buy that pump and backing plate, quite a bit of work to remove all this as car is tight but never trusted driving the car on warm or busy day with traffic and it's almost got to the point of pulling the engine and going a different direction. Even thou I have seen other conversations same type of car no problems all day driving from speaking with them.....

bigblockfordfxstb- Posts : 125

Join date : 2015-06-22

Location : Australia

Re: Still overheating - Water Pump bypass hose?

Re: Still overheating - Water Pump bypass hose?

bigblockfordfxstb wrote:supervel45 wrote:On the hose temperature you could use a laser thermometer when stationary. They do make Fluke strap on probes that could be run in the vehicle for mobile measurements. That kind of monitoring is used in stationary equipment all the time as well as engineering and Lab environments. For what your doing I would shoot for lowest operating temperature, and not get too hung up on it.

Your Email from the above post, Said, styled after an Edelbrock Unit. There have been a lot of people come through these forums and switch to the FlowKooler pumps and solve problems. Randy mentioned it at the beginning of this thread, and I did not Know the CVF Pump you have was like that. You can keep playing with it, and maybe you will make some headway on lowering you slow speed temps but it sure sounds like the pump style to me at this point.

With all that said it also sounds like you have a charging and or undersized/weak battery issue also. The alternator voltages will usually drop a little in high heat conditions from my experience, that's why I said to check it hot and cold with the fans both on and off.

Electric motors also start going bad all the time and drawing higher current too. That's why we always logged amp draws on inspection, to anticipate potential upcoming problems or current ones.

Morning here from Oz... why do you think anything to do with battery or charging is an issue? just curious was it something I mentioned ? I'll check this out I have multimeter for cold and clamp DC style meter also to see...

I do have a Lazer temp monitor, but thinking I have a bung near to rad outlet and possibly a spare temp place for sensor near thermostat and could buy 2 x cheap gauges to looking at this...

as for water pump, I'll see if CVF come back with and possibly look to buy that pump and backing plate, quite a bit of work to remove all this as car is tight but never trusted driving the car on warm or busy day with traffic and it's almost got to the point of pulling the engine and going a different direction. Even thou I have seen other conversations same type of car no problems all day driving from speaking with them.....

_______________________________________________________________________________________

You said in your first post, the fans slowed down due to battery drain. I don't know if you got that fixed but, if they slow down it means less airflow and higher temperature.

You can try the gauges and a bung if it's not too much trouble. It may guide you some on the water system changes that you may make. It's not an end all be all though and without a remotely controlled water

valve/themostat that you could control and look for a few degree's with, it's kinda overkill.

If the Hi Flow thermostat passes the temp. test give it a try. Try no stat and see if it helps if the thermostat does not help.

You can play with the engine tune also. I think I would do that first.

I know it's hard and expensive to get the parts over there, if they come from across the Pond, so I would start with the easiest and cheapist things before going after the pump.

If the CVF pump is a Clone of the Edelbrock, I would just order their backing plate and gaskets if they still offer them, if you wanted to keep that pump.

As much work as it is to replace, Myself, I would just buy the FlowKooler Pump and be done with it.

Sounds like you have had a real bad time of it, if the #unts put the head gaskets on backwards out the gate.

I hope you can make some progress without too much more trouble/expense.

supervel45- Posts : 4487

Join date : 2013-09-04

Re: Still overheating - Water Pump bypass hose?

Re: Still overheating - Water Pump bypass hose?

supervel45 wrote:bigblockfordfxstb wrote:supervel45 wrote:On the hose temperature you could use a laser thermometer when stationary. They do make Fluke strap on probes that could be run in the vehicle for mobile measurements. That kind of monitoring is used in stationary equipment all the time as well as engineering and Lab environments. For what your doing I would shoot for lowest operating temperature, and not get too hung up on it.

Your Email from the above post, Said, styled after an Edelbrock Unit. There have been a lot of people come through these forums and switch to the FlowKooler pumps and solve problems. Randy mentioned it at the beginning of this thread, and I did not Know the CVF Pump you have was like that. You can keep playing with it, and maybe you will make some headway on lowering you slow speed temps but it sure sounds like the pump style to me at this point.

With all that said it also sounds like you have a charging and or undersized/weak battery issue also. The alternator voltages will usually drop a little in high heat conditions from my experience, that's why I said to check it hot and cold with the fans both on and off.

Electric motors also start going bad all the time and drawing higher current too. That's why we always logged amp draws on inspection, to anticipate potential upcoming problems or current ones.

Morning here from Oz... why do you think anything to do with battery or charging is an issue? just curious was it something I mentioned ? I'll check this out I have multimeter for cold and clamp DC style meter also to see...

I do have a Lazer temp monitor, but thinking I have a bung near to rad outlet and possibly a spare temp place for sensor near thermostat and could buy 2 x cheap gauges to looking at this...

as for water pump, I'll see if CVF come back with and possibly look to buy that pump and backing plate, quite a bit of work to remove all this as car is tight but never trusted driving the car on warm or busy day with traffic and it's almost got to the point of pulling the engine and going a different direction. Even thou I have seen other conversations same type of car no problems all day driving from speaking with them.....

_______________________________________________________________________________________

You said in your first post, the fans slowed down due to battery drain. I don't know if you got that fixed but, if they slow down it means less airflow and higher temperature.

You can try the gauges and a bung if it's not too much trouble. It may guide you some on the water system changes that you may make. It's not an end all be all though and without a remotely controlled water

valve/themostat that you could control and look for a few degree's with, it's kinda overkill.

If the Hi Flow thermostat passes the temp. test give it a try. Try no stat and see if it helps if the thermostat does not help.

You can play with the engine tune also. I think I would do that first.

I know it's hard and expensive to get the parts over there, if they come from across the Pond, so I would start with the easiest and cheapist things before going after the pump.

If the CVF pump is a Clone of the Edelbrock, I would just order their backing plate and gaskets if they still offer them, if you wanted to keep that pump.

As much work as it is to replace, Myself, I would just buy the FlowKooler Pump and be done with it.

Sounds like you have had a real bad time of it, if the #unts put the head gaskets on backwards out the gate.

I hope you can make some progress without too much more trouble/expense.

Arrr yes --- ok reason for that comment is because the motor appears to be endless hot at low speed / stop start minor traffic and you can watch the battery in the logs drain.... down to the point it wont kick over. sure if was higher RPM or moving at speed then ALT and cooling not so much of a problem....

I've played with turning already , advance / retarding - AFR etc but no real difference at all to the temps -

As for the backing plate , I dont recall if it was supplied or not, will wait to see if CVF reply or ill call them - I remember it was NEW so either I ordered it or it came with pump... I do recall it being pressed with an indentation in the plate at the impeller and I do recall it would go one way----

just checked flow website , and of course its out of stock - but before I do anything I need to confirm then with CVF if this a replacement to suit all the pulleys / etc etc ....

Also with Flow pump (If I can source one? Summit?) guess I need to confirm with them what backing place to buy also as dont want to be doing this 3 x times....

https://flowkoolerwaterpumps.com/collections/hi-flow-water-pumps/products/1651-1970-1992-ford-429-460-water-pump

bigblockfordfxstb- Posts : 125

Join date : 2015-06-22

Location : Australia

Re: Still overheating - Water Pump bypass hose?

Re: Still overheating - Water Pump bypass hose?

Found an OLD email before I ordered the CVF KIT----- they did supply the backing plate.....

From CVF

All hardware will come with the brackets for mounting the accessories. The water pump will come with backing plate and gasket but not the mounting bolts.

Let me know if there is anything else that I can help with.

Support Team

From CVF

All hardware will come with the brackets for mounting the accessories. The water pump will come with backing plate and gasket but not the mounting bolts.

Let me know if there is anything else that I can help with.

Support Team

bigblockfordfxstb- Posts : 125

Join date : 2015-06-22

Location : Australia

Page 1 of 4 • 1, 2, 3, 4

Similar topics

Similar topics» water pump bypass tube

» Hose between intake and water pump

» Identify Water Pump Markings - PH366 - Overheating problems.... 460

» fuel bypass hose connection

» Switched from mech water pump to Moroso electric water pump

» Hose between intake and water pump

» Identify Water Pump Markings - PH366 - Overheating problems.... 460

» fuel bypass hose connection

» Switched from mech water pump to Moroso electric water pump

Page 1 of 4

Permissions in this forum:

You cannot reply to topics in this forum